Bronze ALU in few figures

90

more than 90 years of experience in foundry

200

more than 200 employees within Bronze Alu

2

production sites

France and Romania

1 300 000

annual parts production record

80 %

of sales are exported

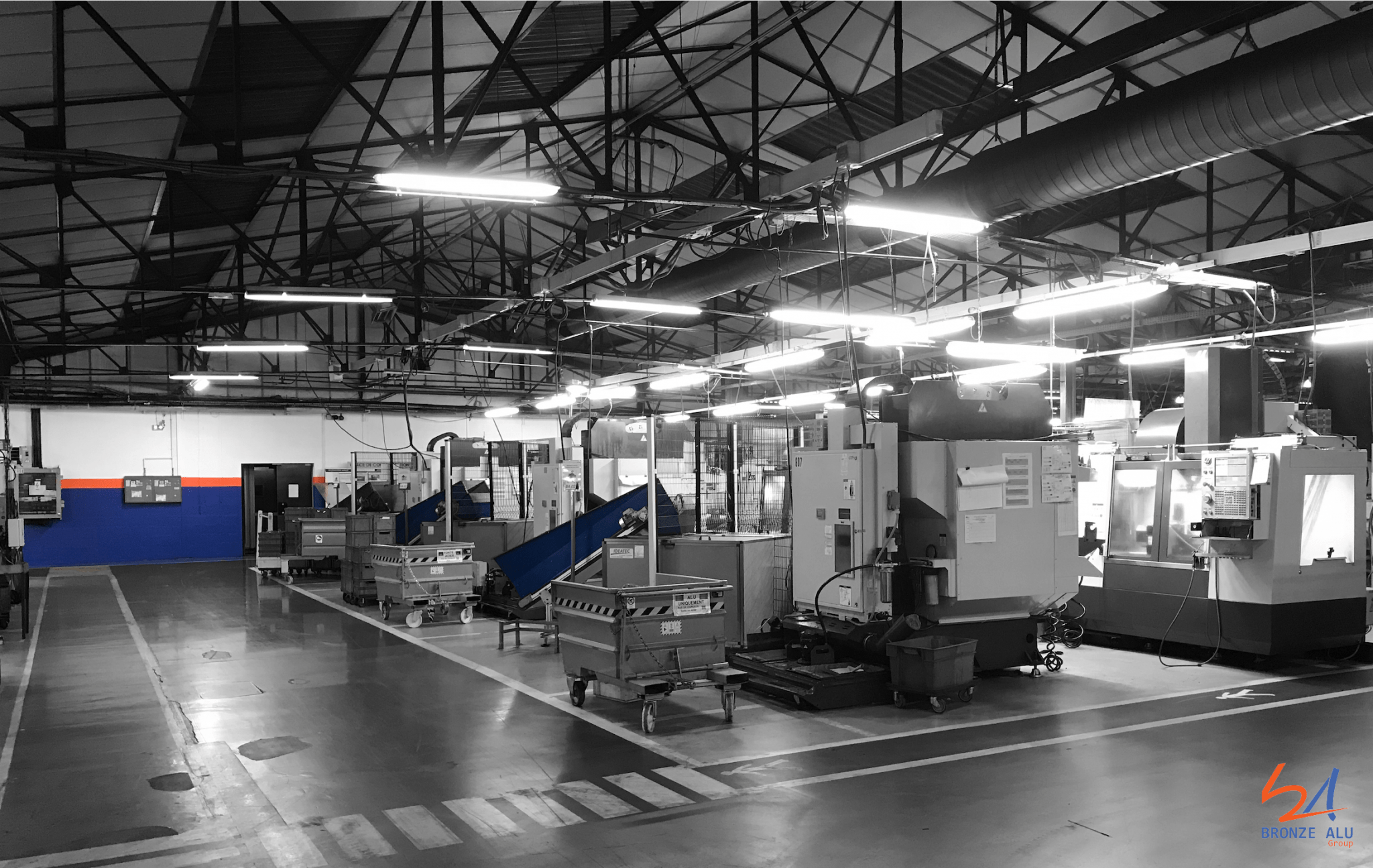

22 000 m²

of production shop floor

Our key dates

1927 - Company creation

Foundation in France of Fonderie du CUPRO-ALUMINIUM by Marcel SCHAAD and his brother.

1958 -

The company is renamed 'Bronze Acior'

1964 - Innovation

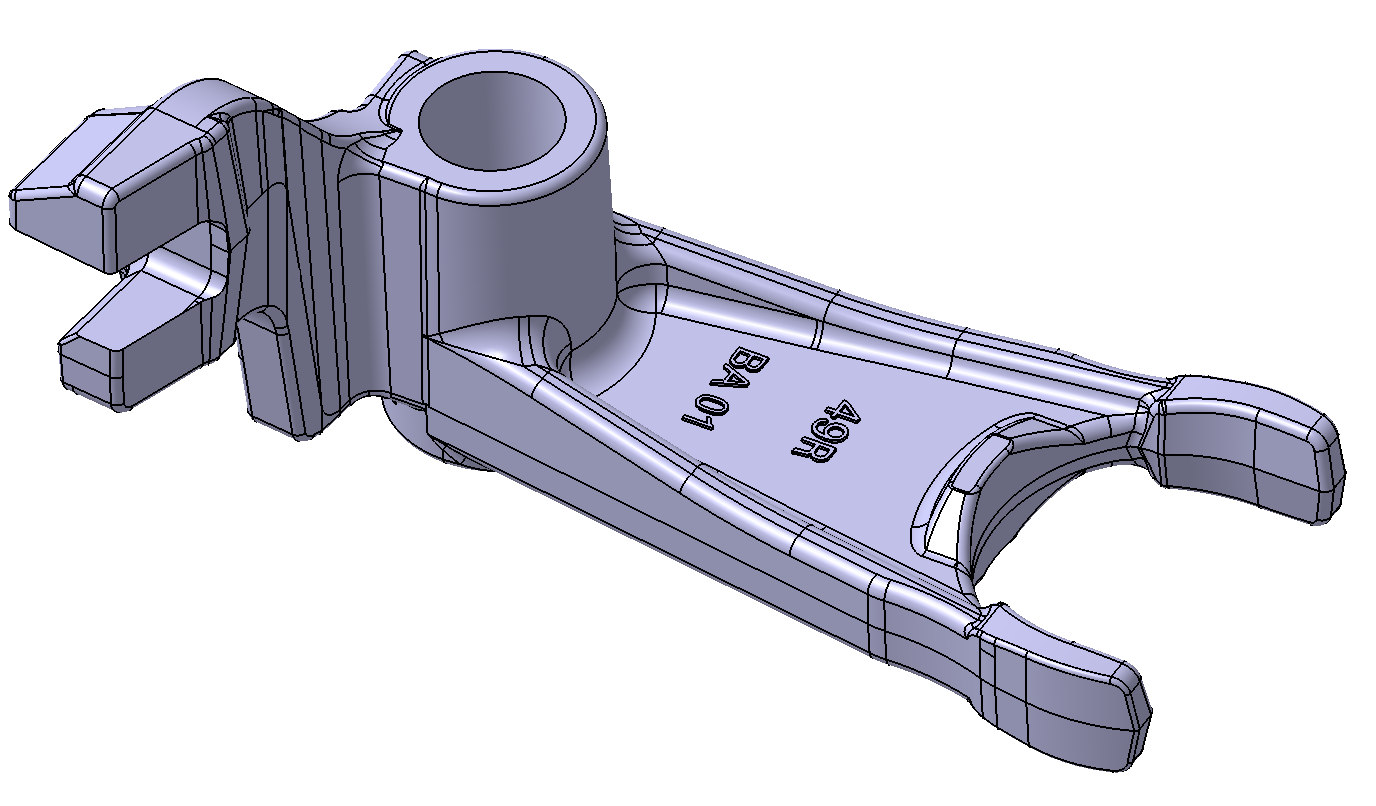

Creation of the first gearbox fork for RENAULT 4L.

1977 - Move

The factory is transferred to LA COUTURE BOUSSEY (Eure)

2004 -

On July 12, BRONZE ACIOR is taken over by Francis BARGE, to become BRONZE ALU SAS.

2006 - Certification

Obtaining ISO TS 16949 certification v. 2002

2006 - Aluminum

First piece manufactured by high pressure injection of aluminum

2007 - subsidiary in romania

Creation of BRONZE ALU CARPARTI in Romania (Pittesti)

2014 - aerospace

First part for aerospace

2018 -

New visual identity

Our Markets

Our certifications

Quality

Quality commitment

Management

Quality Management

Environment

Respect the environment

Men and women committed to common success

The development of BRONZE ALU is performed thanks to the active participation of its employees. Engineers and specialized technicians from our research department put their multidisciplinary skills and their experiences to your benefit.

They are attentive to your requirements, related to your product, your manufacturing process, to ensure the best responsiveness and success for your serial starts.

Research and development

Bronze Alu is consistantly looking for the best engineered solutions and processes for its customers Bronze Alu has partnerships with universities and owns several patents

QUICK CUSTOMIZED SOLUTIONS

For an aerospace customer, Bronze Alu succeeded in less than 4 months to go from early design to full production

Steps involved development of a new alloy ( and its specific heat-treatment), prototypes and setup of serial processes & suppliers

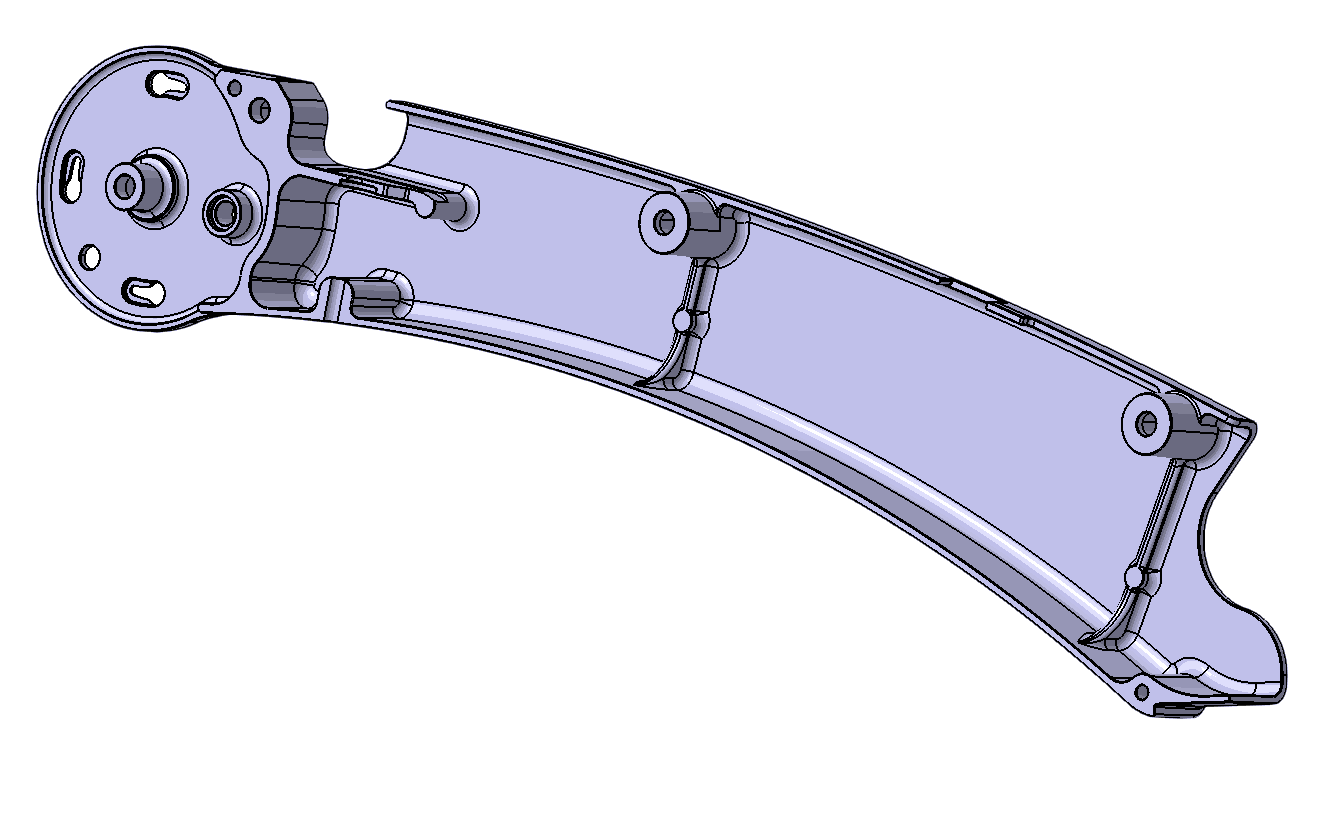

Design to cost

Developing a high resisting aluminum alloy has allowed Bronze Alu to design & manufacture a 100% aluminum gearbox fork, with neither steel bracket nor plastic overmolding for higher customer value

Co-engineering

Bronze Alu has its own R&D and engineering capabilities :

• Dedicated PhDs & technicians

• CAD stations

• Magma Simulation

• Metalurgy lab

• Mechanical test lab

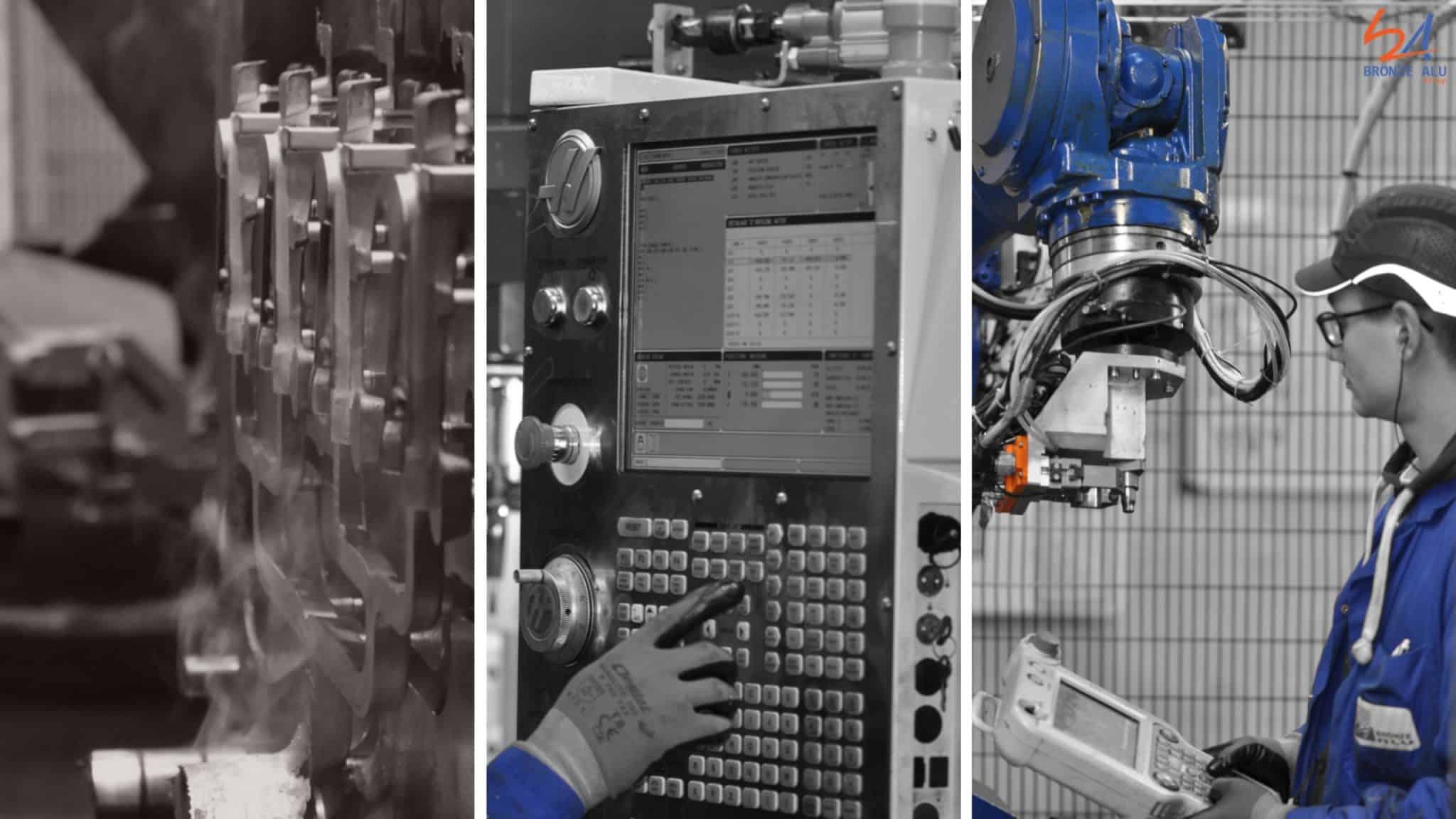

AUTONOMOUS LINES OF PRODUCTION

Same team is managing the manufacturing of its products from raw material to shipping

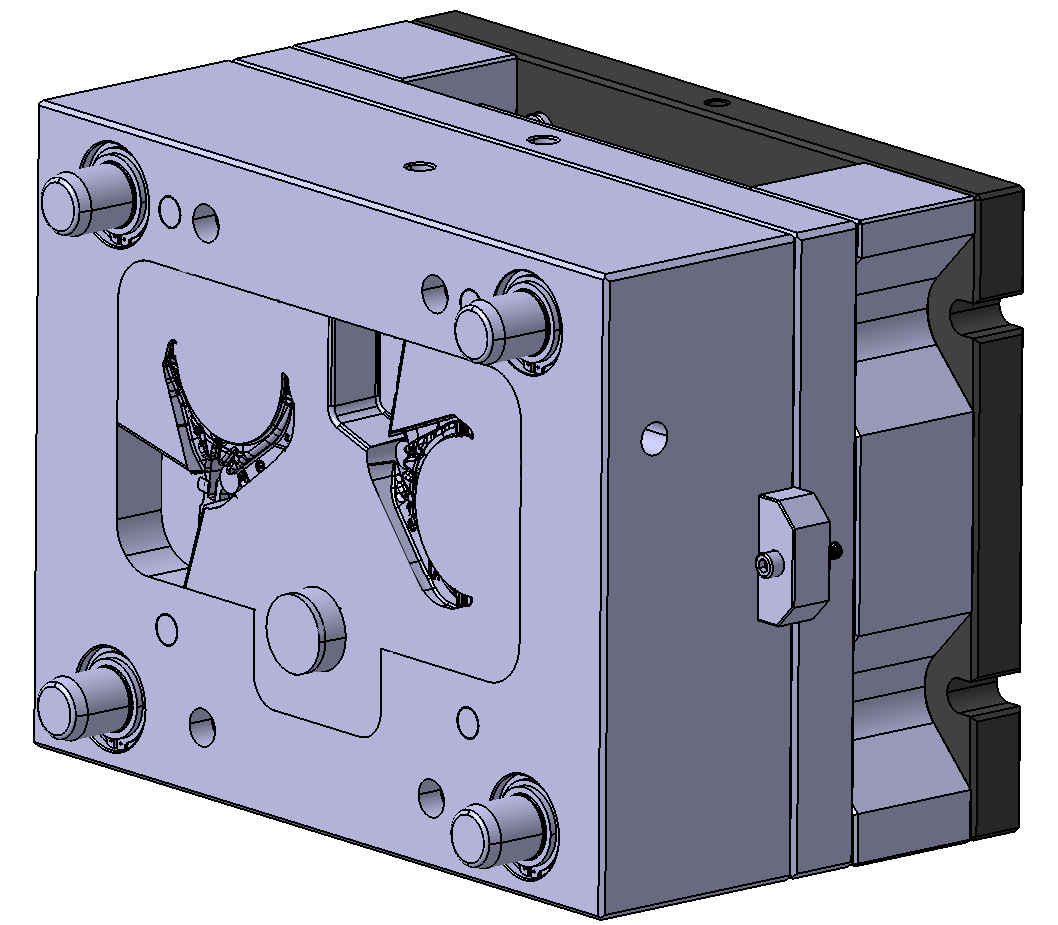

Foundry

Bronze Alu has a wide range of casting units to feed its next dowstream processes:

• 15 HPDC untits from 180T to 1100T for aluminum parts

• Several gravity die casting units for copper-aluminum parts

Bronze Alu designs its injection molds ans maintains them in its own toolshop.

Machining

Bronze Alu masters the turning and machining of very diversified sources of :

• Raw castings

• Forgings from various materials

Assembly

Bronze Alu delivers finished-to-print parts by managing whole supply chain, through internal means and competitive external supply chain, including:

• Mechanical & welded assembly

• Plastic injection

• Surface coating

• Induction-hardening

• Sandblasting, polishing,tumbling

• X-ray inspection

• Dimensional control

Automation vs low cost

Bronze Alu implements very automated lines for high volumes and high quality requirements

Whenever volumes are much lower and labor content is high, manufacturing is made in a low cost site

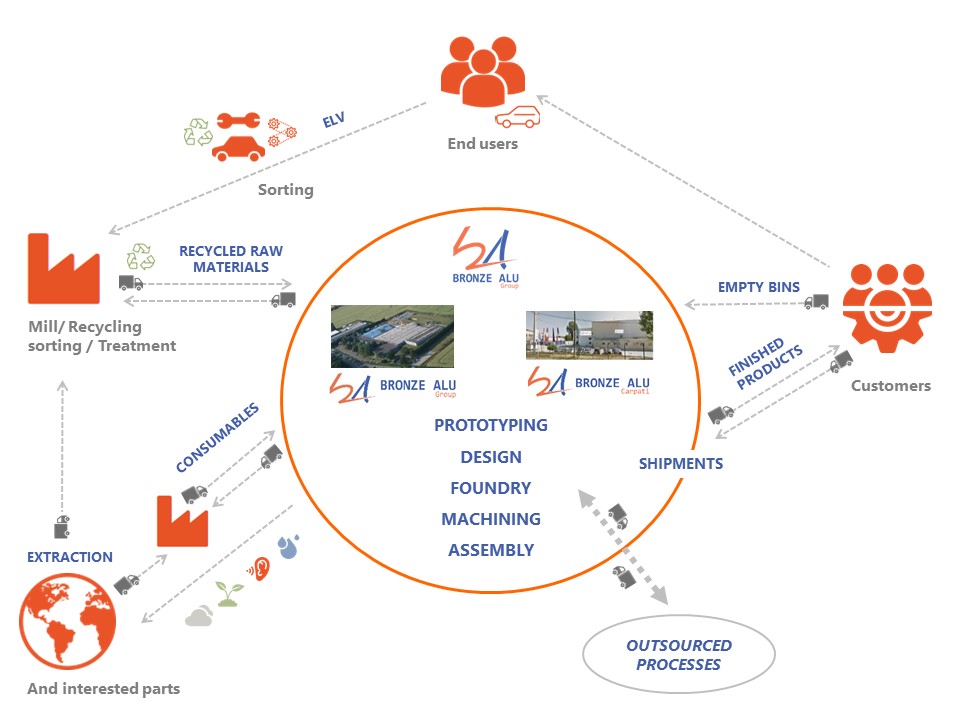

WITH A 100% RECYCLABILITY RATE OF ITS PRODUCTS, BA GROUP ALSO CONTRIBUTES TO THE PRESERVATION OF OUR NATURAL RESOURCES BY USING ONLY RECYCLED RAW MATERIALS FOR THE PRODUCTION OF ITS ALLOYS.

WITH A 100% RECYCLABILITY RATE OF ITS PRODUCTS, BA GROUP ALSO CONTRIBUTES TO THE PRESERVATION OF OUR NATURAL RESOURCES BY USING ONLY RECYCLED RAW MATERIALS FOR THE PRODUCTION OF ITS ALLOYS.